地球温暖化防止

IPCC(国連気候変動に関する政府間パネル)の第6次評価報告書では、温暖化の原因が人類の排出した温室効果ガスであることは「疑う余地がない」と断定し、今後20年以内に産業革命期からの平均気温が1.5℃上昇する可能性が高いことが示されました。温暖化の原因は人類が排出する温室効果ガスであり、その排出を抑制して地球温暖化の進行を緩和させることが急務の課題となっています。カゴメグループは事業活動における温室効果ガス(CO2)の排出を削減し、人類の喫緊の課題である地球温暖化の緩和に取り組んでいます。

CO2排出量の削減の考え方

カゴメグループは安全な原料を調達し、自然の恵みを活かしたものづくりに取り組んでいます。このため事業の最大のリスクを原料調達の途絶と考えています。地球温暖化による大型台風や暴風雨などの異常気象は、原料産地に大きな被害を及ぼします。このリスクを回避し、将来に渡り事業活動を継続するために、パリ協定(※)を率先して遂行し、温室効果ガスの排出量削減に積極的に取り組んでいます。

※パリ協定:2015年12月12日、COP21で採択された気候変動抑制に関する国際協定

(世界の平均気温上昇を産業革命以前に比べて2℃より十分低く保ち、1.5℃に抑える努力をする)

また、カゴメグループでは、CO2排出量の削減をより効果的に進めるため、主要製品のライフサイクルにわたるCO2排出量(カーボンフットプリント)の把握を進めています。

目標

| 区分 | 課題 | 2025年のKPI | |

| 1.地球温暖化防止 | カゴメグループ温室効果ガス(GHG)中長期削減計画の遂行 | 2050年カーボンニュートラルの実現に向け、カゴメグループのGHG排出量の総量削減 |

Scope1・2:20年比21%以上削減 (114千t-CO2e以下) |

|---|---|---|---|

|

Scope3:20年比6.5%以上削減 (1,230千t-CO2e以下) |

|||

| 太陽光発電の導入 | 1工場に追加導入 | ||

| バイオマスエネルギー活用 | 2工場に導入 | ||

| サプライヤー・委託先のCO2削減の推進 |

総量を5.2%削減 (2021年比) |

||

| 物流におけるCO2毎年1%削減(生産量あたり) |

原単位を4%削減 (2021年比) |

||

Scope1:事業者自らによる温室効果ガスの直接排出(燃料の燃焼、工業プロセス)

Scope2:他社から提供された電気、熱・蒸気の使用に伴う間接排出

Scope3:Scope1、Scope2以外の間接排出(事業者の活動に関連する他社の排出)

主な取り組み

再生可能エネルギーの利用

( )内は導入年です。

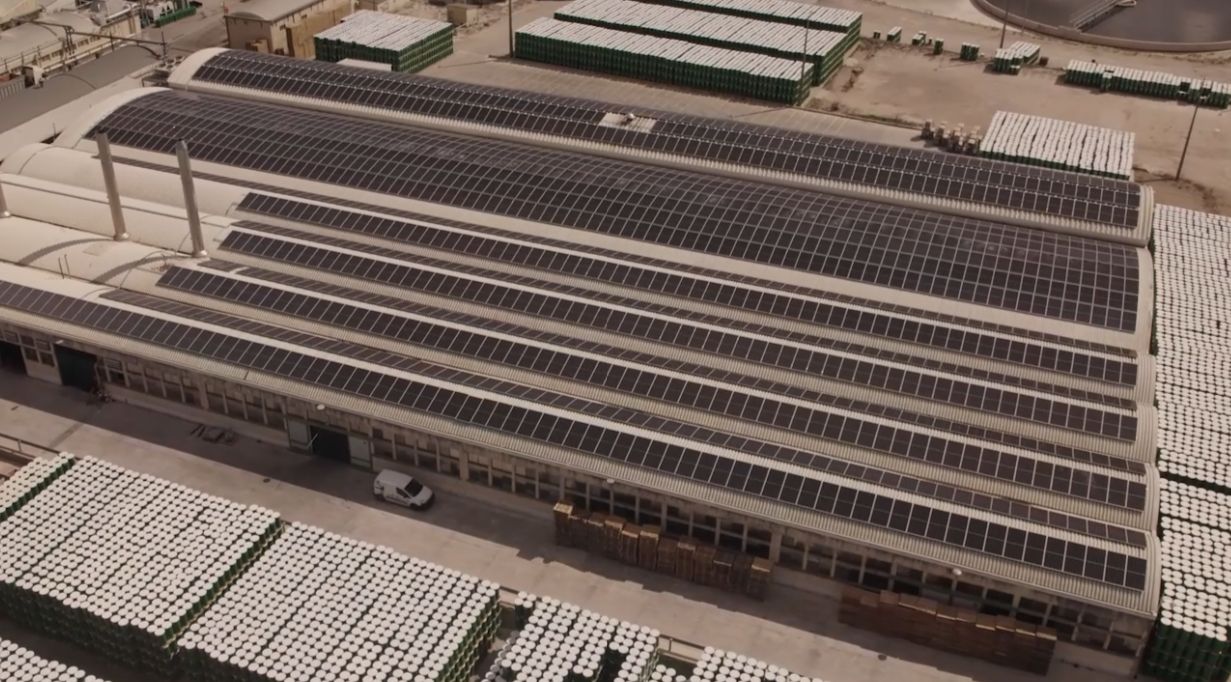

太陽光の利用

国内:小坂井工場(2021年)、茨城工場(2021年)、富士見工場(2021年)

海外:Kagome Inc.(アメリカ)(2017年)、Kagome Australia Pty Ltd.(2019年)

Holding da Industria Transformadora do Tomate,SGPS S.A.(ポルトガル)(2023年)

Holding da Industria Transformadora do Tomate,SGPS S.A.(ポルトガル)

再生可能エネルギー電源に由来する電力を購入して利用

国内:小坂井工場(2022年)、上野工場(2023年)、富士見工場(2023年)、響灘菜園(2013年)

海外:Holding da IndustriaTransformadora do Tomate,SGPS S.A.(ポルトガル)(2021年)

富士見工場(長野県)

バイオマスエネルギーの利用

「カゴメトマトジュース」や「野菜生活 100」等の飲料製品の生産や飲料の原材料むけに生野菜を加工している富士見工場(長野県)において、2023 年 1 月から、当工場から発生する野菜の残渣や当工場の隣にある八ヶ岳みらい菜園の出荷できないトマト等を、再生可能エネルギーとして利用しています。化石燃料の使用量低減により、CO2排出量の削減を実現します。

2023年は、化石燃料由来のCO2排出量を14.5t削減しました。

省エネルギー活動

国内工場における取り組み

生産活動では天然ガス(LNG)、電力など多くのエネルギーを使用するため、国内全工場で省エネ活動を展開して、効率的にエネルギーを利用しています。

国内工場では毎年、省エネキャンペーンを実施しており、エネルギー使用におけるムダやロスを削減するアイデアを募り、優れたアイデアを表彰して、省エネへのモチベーションを高めています。

全工場において、老朽化した設備の省エネ仕様設備への更新や、運転制御方法の効率化、 温排水からの熱回収などに積極的に取り組み、CO2排出量の削減に効果を上げています。

工場内照明のLED化

2023年の省エネ事例

| 区分 | 省エネ事例 | 導入工場 |

| 電力使用量の削減 | 照明のLED化 | 那須 |

|---|---|---|

| コンプレッサーの更新 | 上野 | |

| 空調の更新 | 小牧 | |

| 圧縮空気系統の見直し | 小坂井 | |

| ガス使用量の削減 | 配管の保温 | 茨城、那須 |

| ライン洗浄条件の見直し | 上野、小坂井 | |

| ボイラー台数適正化 | 那須 | |

| ヒートポンプ導入による排熱利用 | 那須 |

海外工場における取り組み

カゴメグループの海外工場は、トマトの搾汁・濃縮工程において多くのCO2を排出するため、設備のエネルギー効率改善や生産効率の向上など省エネ活動に積極的に取り組んでいます。

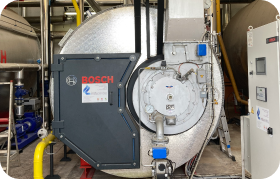

主な省エネ事例

・高効率のボイラーへの更新や運転制御の改善によるエネルギー効率向上

・蒸気配管等の断熱によるエネルギーロス削減

高効率のボイラーへの更新

本社、営業部門、総合研究所における取り組み

クールビズ、ウォームビズの推奨、照明数の削減や小まめなスイッチオフ、複合機導入による事務機器の削減等により省エネを推進しています。更には、働き方の改革として、勤務時間のフレックス化、リモート会議の活用、オンラインでの個人スケジュールの共有等による業務の効率化を進め、オフィス内でのムダな電力使用を抑制しています。

また営業部門においては、営業車の使用方法を工夫することにより、ガソリン消費によるCO2排出の抑制に努めています。

大型トマト温室(菜園)における取り組み

カゴメグループは生鮮トマトを1年中、安定的に市場にお届けするため、温室でトマトを栽培しています。カゴメが直接管理する大型トマト温室(菜園)では、栽培に適切な温度を保つため暖房を使用しますが、その熱源には、環境に優しいLPガスを使用し、さらに、燃焼時に発生するCO2をトマトの生育に必要な光合成に有効に利用しています。

八ヶ岳みらい菜園(長野県富士見町)では、2020年から、隣接する富士見工場の排温水やボイラー排ガス中のCO2の一部をトマト栽培に利用しています。

工場の排CO2を菜園に送る配管

調達・物流部門の取り組み

調達部門における取り組み

温室効果ガス排出量の削減において、特に Scope3排出量の削減には、 より多くのサプライヤーを巻き込むことが重要であると考えています。

サプライヤーの温室効果ガス排出量削減目標・課題の把握、及び、排出量の算定支援など、気候変動の分野におけるサプライヤーとの協働を進めています。

物流部門における取り組み

カゴメは省エネルギー法で定める 「特定荷主(※1)」に該当します。

今後も大型輸送車の使用比率の拡大、往復輸送の推進による車両台数削減、輸配送距離の短縮、共同配送の推進、ルート別輸送頻度見直しによる積載率の最適化などの取り組みを強化し、輸配送におけるCO2排出量の削減を進めていきます。

※1)事業活動に伴って貨物輸送を委託している量(自家物流を含む)が年間3,000万トンキロ以上となる事業者

・モーダルシフト

カゴメは製品輸配送時における環境負荷低減の取り組みとして、鉄道などのより環境負荷の低い輸配送手段に切り替える「モーダルシフト」を継続して推進しています。これにより、鉄道輸送を積極的に行っている企業として国土交通省が認定する「エコレールマーク」の認定企業となっています。

・共同配送の取り組み

2015年から、食品メーカー6社※の共同による効率的で安定的な物流体制の実現を目的とした物流プラットフオーム構築の検討を開始し、2019年4月に食品メーカー5社※による共同物流会社F-LINE(株)を設立しました。

F-LINE(株)は、(1)共同配送体制の全国への展開、(2)中距離幹線輸送の再構築、(3)物流システムの標準化等を目指しており、昨今のトラックドライバー不足や物流コストの上昇、CO2削減をはじめとする環境保全への対応など、物流を取り巻く諸課題の解決を目指しています。

※食品メーカー6社:味の素、ハウス食品グループ、カゴメ、日清製粉ウェルナ、日清オイリオグループ、Mizkan

※食品メーカー5社:味の素、ハウス食品グループ、カゴメ、日清製粉ウェルナ、日清オイリオグループ

F-LINE(株)