資源の有効活用

目標

| 区分 | 課題 | 2025年のKPI | |

| 2.資源の有効活用 | 1)原料調達から製品流通における食品ロスの削減 | 原料の廃棄削減 |

原料廃棄量の50%削減 (2018年比、2030年目標) |

|---|---|---|---|

| 製品(仕掛品、商談サンプル含)の廃棄削減 |

製品廃棄量の50%削減 (2018年比、2030年目標) |

||

| 2)カゴメプラスチック方針の実働 |

・石油から新たにつくられるプラスチックの使用抑制 ・資源循環が可能なリサイクル素材や植物由来素材への置き換え推進 |

石油由来素材のストローの使用ゼロ化(2030年目標) | |

| リサイクル素材又は植物由来素材への50%以上置き換え(2030年目標) | |||

| 3)廃棄物のリサイクルによる資源循環の推進 | ゼロエミッションの継続 | ゼロエミッションの維持 | |

| 食品廃棄物の削減とリサイクル率の維持 | 食品リサイクル率95%以上の維持 | ||

原料調達から製品流通における食品ロスの削減

原料・製品の廃棄削減の取り組み

カゴメはSDGsの目標12の「2030年までに小売・消費レベルにおける世界全体の1人当たりの食料の廃棄を半減させ、収穫後損失などの生産・サプライチェーンにおける食料の損失を減少させる」に賛同し、目標を定めています。

原料・製品の廃棄を削減するため、商品設計段階における原料滞留リスクの抽出と対策、生産量の精度向上、品質不良品発生の撲滅、原料・製品の滞留可能性が出てきた段階での対策等により、原料・製品の廃棄削減を進めています。

2030年の目標(原料・製品廃棄量の50%削減,2018年比)に対し、2023年度は原料・製品ともに廃棄量を50%以上削減しました。

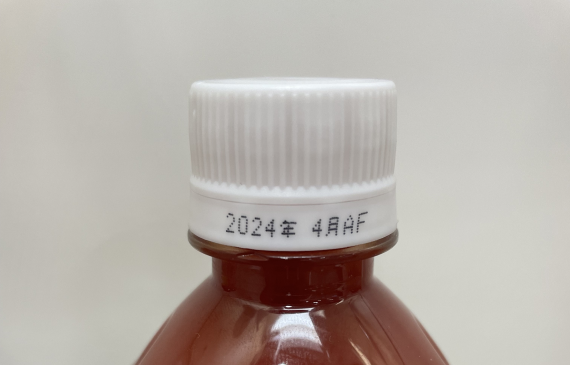

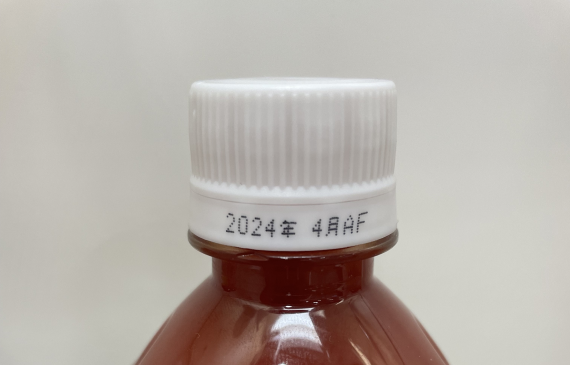

賞味期限の年月表示の取り組み

食品ロス削減や物流・倉庫・小売りなどの流通関係者の負担軽減を目的とし、2020年10月から賞味期間が360日以上の家庭用飲料商品(缶・PETボトル)を対象として、賞味期限表示を「年月日」から「年月」へと順次変更しています。

食品廃棄物の抑制と再生利用 ~食品リサイクル法への対応~

食品リサイクル法では、食品廃棄物等の排出の抑制と、資源としての有効利用の推進(再生利用)を食品関連事業者に義務付けています。食品製造業における再生利用等の実施率は95%を達成するよう目標が設定されています。

カゴメは植物性残渣や廃棄商品の処分において、分別の強化や再生利用可能な処理業者の選択等を行うことで、食品リサイクル法の定める再資源化を進めています。

再生利用等の実施率は、2017年度以降、目標である95%以上を達成しています。

カゴメ プラスチック方針の推進

カゴメ プラスチック方針

海洋に流出するプラスチックごみが海洋生物の生存を脅かし、人体にも悪影響を及ぼすなど、世界的な環境問題となっており、この問題への対応が急務となっています。

カゴメは、プラスチックを有用な素材として今後も適切に利用する一方で、石油由来のプラスチック量を削減し、その資源循環に貢献することを目的に、2020年に『カゴメ プラスチック方針』を制定しました。この方針に則り、プラスチックの使用量削減や素材代替、リサイクル等に取り組んでいます。

全清飲“2030年ボトルtoボトル50%宣言”への賛同

使用済みペットボトルをリサイクルして再度PETボトルとして利用する“ボトルtoボトルリサイクル”は、何度も繰り返してリサイクルできるため、環境への負荷が少ないリサイクルとされています。

カゴメも加盟する全国清涼飲料連合会(全清飲)は、2021年4月、このボトルtoボトルリサイクル率を2030年までに50%以上に引き上げるとした目標を発表しました。カゴメもこの動きに連動し、業界や容器メーカーと協力してボトルtoボトルリサイクルに積極的に取り組んでいきます。

廃棄物のリサイクルによる資源循環の推進 ~ゼロエミッションへの取り組み~

リサイクルセンター

カゴメは生産余剰物の再資源化のために工場敷地内にリサイクルセンターを設置しています。

たとえば、富士見工場では、ドラム缶やプラスチック容器、金属くず等を19区分63分類に細かく分別し、個別業者の回収まで再資源化の材料として大切にストックしています。また、リサイクルセンターでは、外からよく見えるようにすることで、保管物の正しい分別・整理を徹底しています。

ゼロエミッションの達成・維持

カゴメは原料農作物を無駄なく使用することはもちろん、すべての生産余剰物の削減と再資源化に取り組んでいます。生産余剰物のうち、植物性余剰物・汚泥については2001年度に100%再資源化を達成し、以後その維持に努めています。また、2005年度に自社6工場でゼロエミッション※を達成し、東日本大震災の影響による2011年度および2012年度を除き、その後もゼロエミッションを維持しています。

※カゴメは自社基準に基づき生産余剰物の99%以上を再資源化することをゼロエミッションと定義しています。

有害廃棄物の管理

生産活動では、洗浄用薬剤や殺菌剤、分析試薬、燃料等の化学物質を使用しています。これらの物質が貯蔵または使用中に流出することなく、また廃棄や大気排出にあたっては、周辺環境の汚染や人への健康危害の原因にならないよう、法令を順守し適切に管理を行っています。

2023年度において、上記物質の漏洩や基準超過等、環境に影響する重大な事故および違反は発生しておりません。また将来発生しうるコスト(シャドウコスト)はありません。